Supply chains are the lifeblood of any company. The healthy flow of goods, services, information and money throughout the end-to-end supply chain is critical to business success. Disruptions in the supply chain are an inevitable part of doing business. Whether it’s a devastating natural disaster such as Hurricane Michael or political events such as the recent trade wars, it’s not a question of “if” but “what” variety and “when” the next interruption is going to occur.

Why all the buzz about supply chain risk management?

As the saying going “we live in a global economy”; global supply chains have extended pipelines and more complexity, hence, are much more susceptible to disruptions such as natural disasters, supplier quality and performance issues, economic and political instability. The larger the footprint of your supply chain, the greater the odds you’ll face one or more of these adverse events.

The infamous Japan Tsunami of 2011 forced General Motors to close plants in the U.S. due to part shortages from Japanese suppliers. They had made the costly mistake of not having a good handle on who their lower tier suppliers were or their locations. The cost to General Motors was reported to be in the millions. They’ve since implemented counter-measures. Nonetheless, it’s a valuable lesson on the importance of taking a holistic approach to supply chain risk management.

With cyber-attacks at an all-time high and terrorism a constant threat, supply chain risk management is rightly garnering considerable attention and focus not only from the global giants, but also from the small and midsize businesses (SMB) where many of them are operating primarily domestic supply chains as well.

Proactive risk management starts with a performance driven strategy

Most companies respond to disruptions by playing defense – i.e. reacting after the fact. Very little offense is played. But the old adage “the best defense is a good offense” is a smart approach to effective risk mitigation. Choosing the best strategy may mean the difference between success and failure. Make no mistake, risk management should begin at the strategic level because it can allow organizations to gain a competitive advantage over less adept rivals by increasing market share when a supply chain disruption occurs.

And that may help explain why many leading organizations are making supply chain agility a strategic priority. The Supply Chain Operations Reference Model (SCOR® is the world’s leading supply chain framework, linking business processes, performance metrics, practices and people skills into a unified structure) defines Supply Chain Agility “as the ability to respond to external influences, the ability to respond to marketplace changes to gain or maintain competitive advantage.” Agility is one of five SCOR® performance attributes used to prioritize and align the supply chain’s performance with the business strategy. Just as you would describe a bank account using standard characteristics such as type of account, balance, and interest rate, a supply chain requires standard characteristics to be described. SCOR® uses Reliability, Responsiveness, Agility, Cost & Asset Management Performance Attributes to describe a Supply Chain Strategy.

Apple and Honda are two examples of successful companies with agile supply chains. Automotive insiders credit Honda’s agility — designing factories to produce a variety of models versus its competitors’ approach of dedicating plants to a specific model — with enabling them to ride out the 2008 recession relatively unscathed.

Get your crew rowing in the same direction.

Imagine participating in Olympic rowing — if just one rower is out of sync it will adversely impact the entire boat and the chances of being victorious are slim to none. While supply chain management isn’t an Olympic event, leading companies such as Amazon, Apple, McDonalds and P& G, to name a few, are successfully using it to gain a competitive advantage.

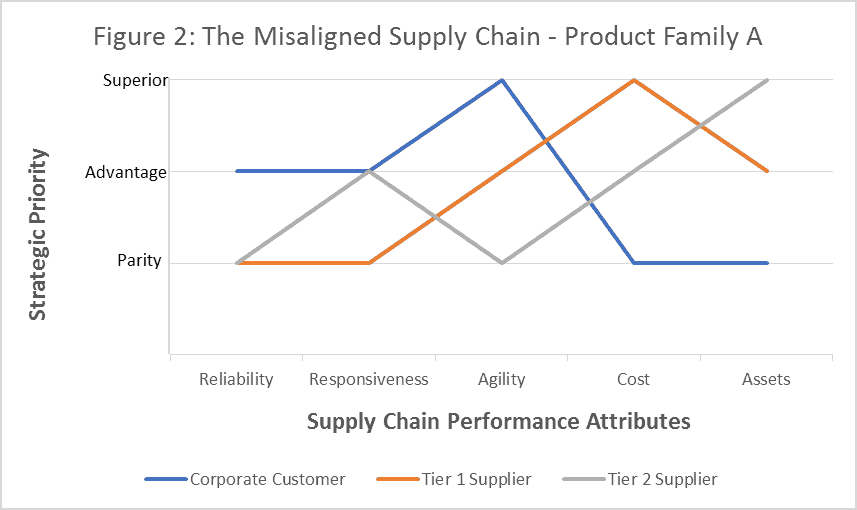

Supply chains that are out of sync strategically as shown in Figure 2 will be misaligned tactically as well and have a challenging road ahead when it comes to implementing an effective risk management program. For example, the corporate customer may choose to make Agility it’s top competitive priority for the Product Family A supply chain, but if key suppliers are competing based primarily on Cost, then this mismatch will lead to suboptimal decisions. These key suppliers will most likely prioritize their resources and investment decisions to projects, programs and solutions that move the needle on cost reduction rather than risk reduction. In this example, the rower’s paddles are colliding and splashing in the water causing the boat to veer off course and quickly decelerate — they’re not even in the race.

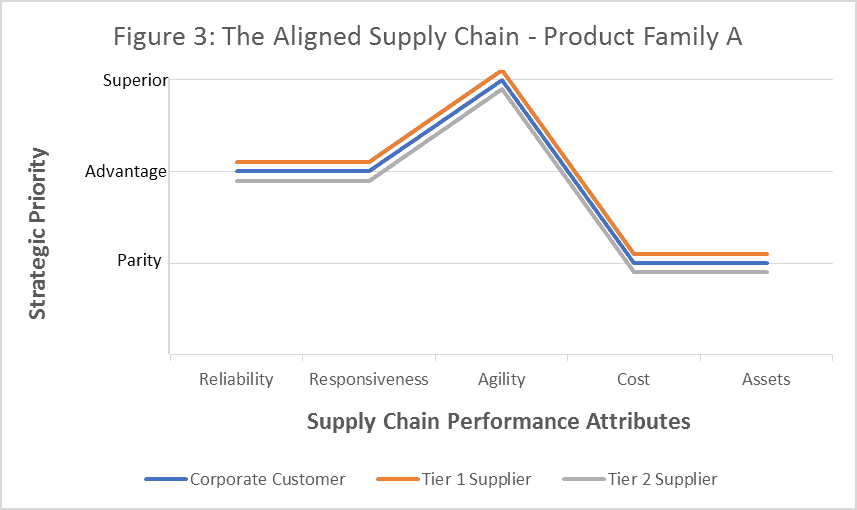

Conversely, an aligned supply chain as shown in Figure 3 offers significant opportunity to gain greater competitive advantage for the supply chain as a whole. Everyone’s on the same page and the end-to-end supply chain is tuned to achieve superior performance in Agility. In this scenario key trading partners are collaborating and sharing information including performance measures and metrics. Risk management is an ongoing agenda item throughout the supply chain network with appropriate KPI’s and cascading metrics that are measured, monitored and continuously improved in an effort to achieve and sustain superior performance. Here the rowers are synchronized in their movement enabling them to propel their boat efficiently and effectively through the water and are on course to win the race.

Note: For the purpose of this discussion, superior performance means ranking in the top 10% of your peer group (advantage = top 25% and parity = in the middle) for a particular level-1 strategic metric as determined by a competitive supply chain benchmarking study such as SCORmark. SCOR® level-1 strategic Agility metrics include Adaptability and Overall Value at Risk.

This strategic alignment approach is most applicable to your key suppliers including strategic partners. For the typical commodity type suppliers with undifferentiated products such as standard fasteners or corrugated boxes, competing primarily on price is a logical choice regardless of the corporate customers supply chain strategy.

How to get suppliers up to speed?

Many suppliers fall into the SMB category, which is typically characterized by thin management, little or no industrial engineering talent, tight budgets and tendency to focus on firefighting. Consequently, they don’t have the horsepower necessary to independently pursue performance excellence initiatives such as a supply chain risk management program and the corresponding strategies.

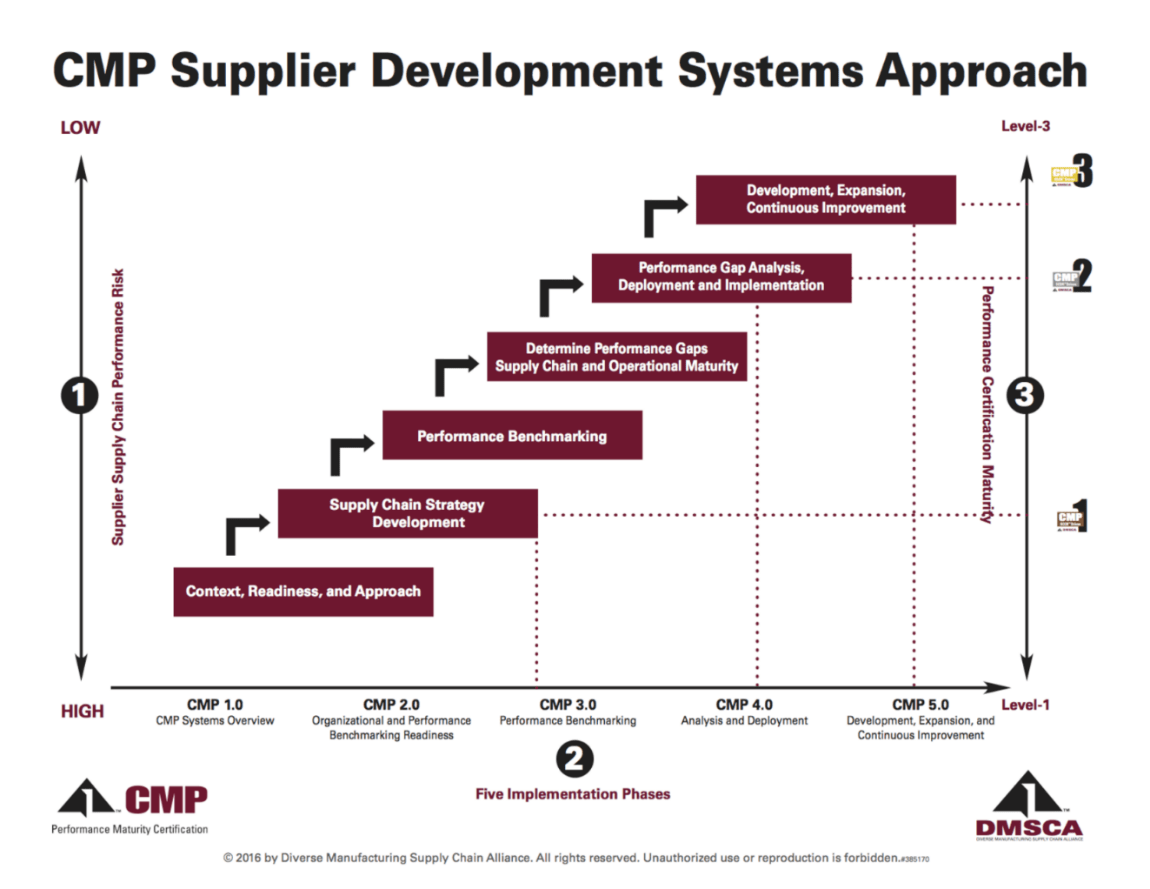

The Diverse Manufacturing Supply Chain Alliance (DMSCA) is a non-profit membership organization offering a unique solution to supplier development and risk management called the Corporate Mentoring Program (CMP). CMP is heavily influenced by the SCOR® framework of supply chain operational excellence and is designed to help SMB’s improve their competitiveness and climb the ladder towards strategic partnerships with their customers.

CMP Supplier Supply Chain Performance Maturity is based on progressive engagement in five implementation phases as shown in Figure 4 – item #2. Supply Chain Performance Maturity is certified at three levels; Bronze, Silver and Gold as displayed in Figure 4 – item #3. Suppliers who reach the CMP level 3 Gold certification have received all of the program education and coaching services and have demonstrated, through live implementation, measurable improvements in supply chain performance.

DMSCA is supported by such Corporate Members as Johnson and Johnson, Caterpillar, McCormick and Co., Merck, , Medtronic, PepsiCo, Owens Corning, Siemens and others.

Figure 4.

Introducing suppliers to tools, techniques and strategies to which they would otherwise be unaware and unable to maximize on their own, is a win-win for both customers and suppliers. First, suppliers learn to become more efficient, which leads to their bottom line results. Second, as suppliers build capability, the opportunity to grow the business and prosper increases as well; the little fish turn into midsize ones and the midsize become the big fish. Third, for corporate customers working with capable suppliers whose strategies are aligned with yours reduces supply chain risk and boosts resiliency.

The bottom line is that a great supply chain is a resilient supply chain and one that can smoothly handle sudden unexpected disruptions. This occurs when supply chain strategies are in sync.

Next Steps

Are you a corporation looking for an alternative approach to developing your supply base and minimizing supply chain risks? Are you a forward-thinking supplier with a desire to expand your capabilities and enhance performance? To learn more about the DMSCA CMP program, visit here: https://www.dmsca.us

References:

APICS (2017). Supply Chain Operations Reference Model SCOR®, (Version 12.0). Chicago, IL: APICS

Jeffrey Miller, P.E., CPIM, SCOR-P, CS&OP leads the coaching, education and training for the DMSCA supplier development and supply chain performance excellence certification system called Corporate Mentoring Program (CMP). He is also founder and managing principal of Productivity Engineering Services LLC – a professional industrial engineering and operations management consultancy driving business performance improvement for clients. Miller has more than thirty years’ experience helping companies of all sizes in a variety of industries including automotive, outdoor power products, bicycle, industrial machinery and heavy equipment, helicopter, consumer goods, distribution/logistics, and general manufacturing/industrial products, make their operations leaner and more productive.

He attended the University of Michigan where he earned both a Masters and a Bachelors of Science degree in Industrial and Systems Engineering. Miller is a registered Professional Engineer (P.E.) in Michigan. He has CPIM and SCOR-P certifications from the association for supply chain management (APICS), and CS&OP certification from the Sales and Operations Planning (S&OP) Institute and the USC Marshall Center for Global Supply Chain Management. Miller is also Certified in Lean Manufacturing by the University of Michigan College of Engineering Center for Professional Development. For more information, visit https://www.pessolutions.com/ or email pr-mrktg@pessolutions.com

David J. Burton, MCP, AICP, is the Founder and CEO of the Diverse Manufacturing Supply Chain Alliance (DMSCA), a multi-tiered membership-based Supplier Supply Chain Excellence Training and Development organization and the DMSCA Supplier Development Foundation, a 501(c) 3 organization that supports Suppliers’ Advance Manufacturing and Workforce Skills development towards community economic development and jobs creation.

Burton obtained his B.S. from the Morgan State College, a Masters from the University of Pennsylvania in City Planning and Regional Science, and was a Doctoral Student at George Washington University in Public Administration. Burton is a former Adjunct Professor in Planning at Howard University and, as a Regular Army Captain, is a decorated Vietnam Veteran.

Burton has also written numerous articles on supply chain related supplier supply chain excellence and economic development issues; serves on the White House Business Council-Business Forward; and, is a Member of the American Institute of Certified Planners (AICP). Burton is a Lifetime Member of the Alpha Phi Alpha Fraternity,

A condensed version of this article originally appeared in SUPPLYCHAINBRAIN

Your article on supply chain management has helped me get well versed with this important topic. Supply chain management is really the need of the hour. A good supply chain is a must for any organization to improve its overall efficiency as well as customer satisfaction. Thank you.

You’re welcome, Raj. I really appreciate you voicing your support. It’s gratifying to know our article was helpful. I agree, SCM is certainly garnering considerable attention these days and rightly so. The more aligned the supply chain is, the better it can perform (just like an in sync Olympic rowing team) and the happier our customers will be. That’s a bona fide win-win.

I am a store owner with three branches in and around the state. While theoretically supply chain management sounds fine but the whole thing was disrupted during the pandemic. Good supply chain management should be ensured to meet any challenges, so the organization don’t suffer. This article is well written penetrating deep into the subject.

Hello Hannah,

Sorry to hear your stores were adversely impacted by the COVID-19 pandemic. Unfortunately, this crisis exposed how brittle our global supply chains truly are. I think it was a real wake-up call for business leaders to become more proactive in developing reliable risk management strategies and plans. I’m glad you found our article to be beneficial and really appreciate your comments and compliment.

All the best!

Jeff

Thanks for thr great article!

Thanks for thr great article!