Factory Layout Design and Operations Improvement

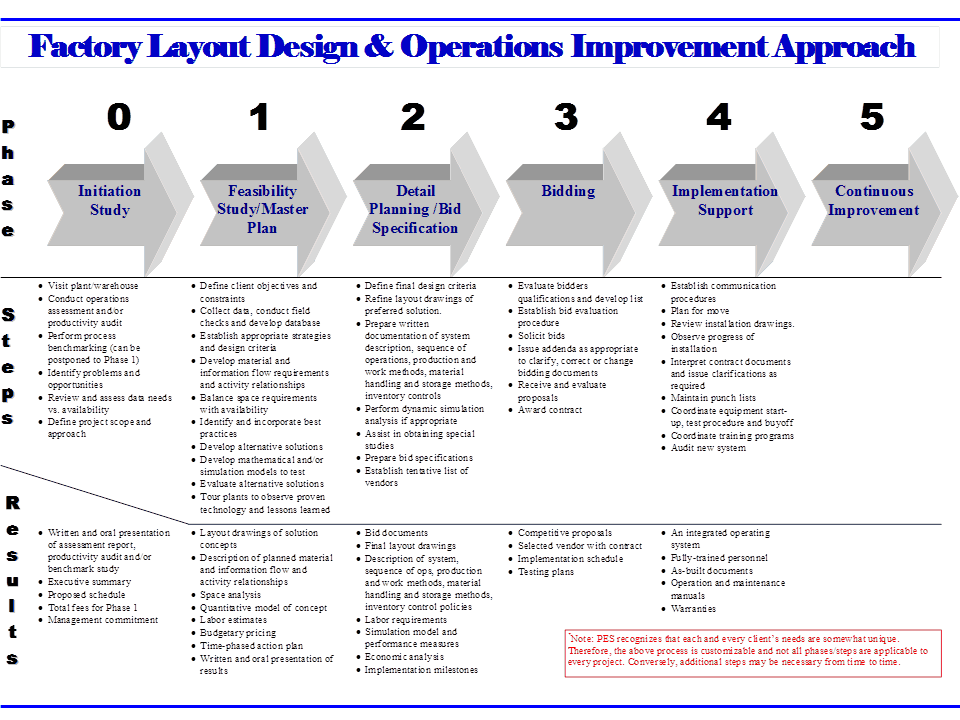

PES’ Proven Phased Approach*

Since 1992, PES has been involved in numerous factory planning and plant layout projects. Over time, we have developed a practical, systematic six-phase approach to ensure projects make good business sense, run smoothly, and deliver what’s promised.

The following page shows the phases involved in a typical project along with the major steps of each phase and examples of deliverables. This methodology is easily adaptable to a variety of projects and clients and not every phase and/or step is required for every project.

This preliminary phase assists companies identify opportunities to improve their operations and determines the direction of subsequent project efforts. The intent of the initiation phase is to define the project in terms of objectives and scope of services, analysis methods, and expected investment, benefits and schedule. It may include an Operations Assessment, Productivity Audit and/or Process Benchmarking Study. The Operations Assessment will identify gaps in the manufacturing or warehousing operations and help prioritize improvement projects. The Productivity Audit will assess the effectiveness of labor utilization and highlight imbalances in workload. The Process Benchmarking Study will provide comparisons of your capabilities and identify best practices.

This phase addresses project/program requirements and solutions in their conception or early planning phases and can assist with critical decisions that directly affect long term business performance. Typical applications include evaluating alternative material handling and storage methods, rearranging plant layout for streamlined flow and exploring modern manufacturing techniques (e.g., lean). This is where the business case is made (establishing project practicality and cost justification).

This phase involves fine tuning the preferred solution (i.e., the solution that is technologically-workable, cost-effective and meets or exceeds the goals and objectives of the project). Bid documents/specifications are prepared that accurately depict and detail project requirements and provide a basis for soliciting truly competitive proposals.

This phase is the actual vendor/contractor selection process. It includes establishing the selection criteria that fit the needs of the project, prequalifying vendors/contractors, soliciting bids from qualified vendors/contractors, processing proposals, awarding the contract based on selection criteria and obtaining a detailed implementation schedule.

This phase is where installation drawings are reviewed and approved, the actual moves to install the machinery, equipment, and systems as designed are made, and the solution is commissioned. Field observation is a critical step in this phase to ensure the work is progressing in general conformance with the design documents to achieve the project objectives.

Once the new solution is in operation, it’s important to follow up to see that it is functioning as planned and the expected ROI is being achieved. In addition, it’s essential to make regular improvements and upgrades to your process to maintain operational excellence. That practice of continuous improvement is not a destination, but rather a journey directed toward sustained quality and productivity.

The Next Step!

Contact PES at (734) 425-3904 to learn how our planning and design services can help deliver phenomenal results for your organization! Don’t worry, you won’t get stuck in an automated phone tree or have to endure a pushy sales rep. This is the direct line to Chief Solutions Officer Jeffrey Miller.

Email: jmiller@PESsolutions.com