Added Value Lean Manufacturing Assessment

Want to Take Your Lean Program to the Next Level?

In order to survive in today’s hypercompetitive environment, many companies are adopting lean techniques; the goal is to delight the customers and make a profit through the relentless elimination of waste from the operations. Unfortunately, that’s easier said than done. Few companies have achieved the kind of sustained success that Toyota has from its legendary lean production system. While many companies have implemented “islands of lean,” what’s often lacking is a comprehensive system. In other words, you may have the best field goal kicker in the league, but if your offense can’t move the ball then it’s difficult to score points and ultimately win games.

So where do you get started if you want to take your lean program to that next level? The first step is to conduct an Added Value Lean Assessment of your plant to determine the current status and relative “leanness” of your operation. Once you have determined your current state, you can properly plan your future and prioritize improvement opportunities so that your targets are realized within the shortest lead time possible.

What the Added Value Lean Assessment Does for You

Whether you’re a mature lean organization or just getting started on your lean journey, PES can help you:

- Understand the state of your operation along a lean transformation path

- Measure your lean index and track its progress

- Measure and compare operational performance to industry peers

- Determine gaps that must be closed to improve your “leanness”

- Identify and prioritize improvement opportunities

- Provide quick information on strengths and weaknesses when evaluating a supplier

- Establish benchmarks for performance improvement

- Learn and apply lean principles and best practices

Of all the potential benefits, perhaps the most valuable is the ability to hit the ground running on your operations improvement journey. There’s no need for analysis paralysis or a lengthy ramp up. The assessment will highlight both long term opportunities and the low-hanging fruit.

How to Determine if Your Factory is Truly Lean

Unlike the one-and-done in-plant assessments and reporting conducted by other firms, PES offers a novel multi-faceted approach that delivers more bang for the buck. PES’ Added Value Lean Assessment is based on a systematic holistic process. This methodology integrates the widely recognized tools and techniques of rapid plant assessment (RPA), performance benchmarking, lean principles and practices into a unified framework – creating an extraordinary synergy.

Rapid Plant Assessment

The Rapid Plant Assessment (RPA) is for quickly evaluating production facilities and identifying improvement opportunities during a plant tour. To the trained eye, a plant tour can reveal a great deal about a company (e.g., lean operations look lean and non-lean operations don’t). RPA is based on lessons learned from numerous successful applications of lean manufacturing in North America and European operations and it’s been shown to be a reliable indicator of a plant’s strengths and weaknesses. Two distinct versions are offered: one for the low-mix, high volume (LMHV) Toyota style manufacturers and another for the high-mix, low-volume (HMLV) Job Shop environments.

The RPA process includes two tools for performing the assessment: the RPA rating sheet which groups over 200 lean operations attributes into 12 categories (see sidebar for 12 categories) for assessing the “leanness” of a plant and the RPA questionnaire which provides a series of associated yes-or-no questions to determine if the plant uses lean principles and best practices in these categories.

Performance Benchmarking

PES believes that lean, like other performance improvement programs, is a means to achieving a goal, not the end goal itself. At the end of the day, the proof is in the performance. The question is, how will you keep score to know whether or not you’re winning?

Effective benchmarking against industry peers is critical to understand performance gaps. The Performance Benchmarking Assessment (PBA) will compare where your company stands relative to organizations in the same industry for key metrics that are aligned to the 12 RPA lean assessment categories. These benchmark metrics will include performance levels of cost, quality, delivery, productivity, and safety.

Through collaboration with one of our professional associations, PES has access to one of the largest databases of manufacturing practices and performance metrics collected from hundreds of facilities around North America. Leveraging this quantitative benchmarking data will help paint a more complete picture of your plant’s “leanness” by shedding light on critical financial and operational performance.

How it Works

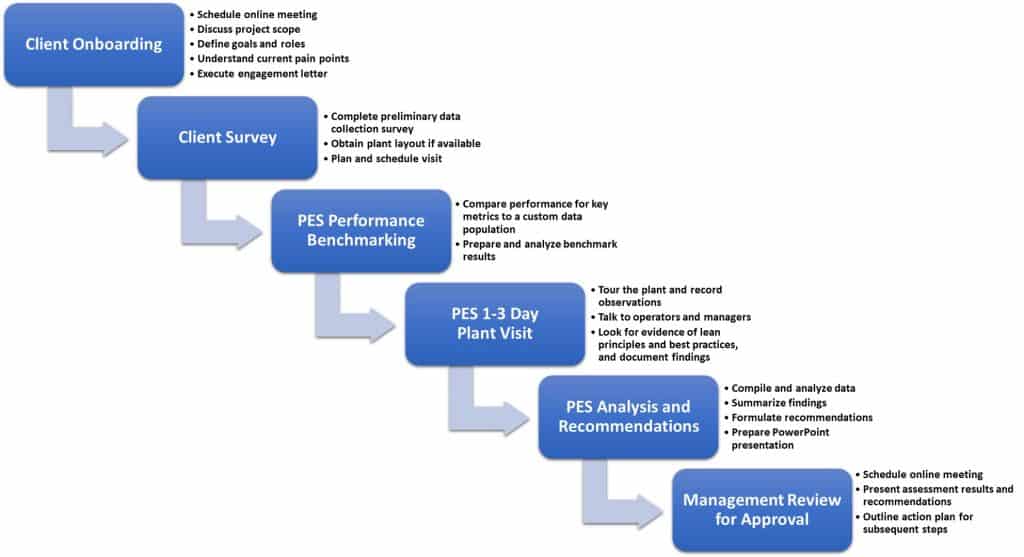

Figure 1

Figure 1 is a high-level flow chart that illustrates the process. In general, the project will kick-off with an online meeting to discuss assessment scope, define goals, understand your current pain points, and develop a preliminary schedule. A formal engagement letter will be drafted by PES and executed by both parties.

PES will provide you with an Excel file (the benchmark survey) to gather basic information about your company, its’ operations and key metrics. Once you’ve completed and returned the confidential survey, PES will review your submission for completeness and any obvious mistakes or misinterpretations. Once the survey is finalized, we will prepare and analyze your benchmark results. The results will be included in the final PowerPoint presentation discussed below.

Next, we’ll schedule the plant visit. Prior to the assessment, the rater(s) will become familiar with the general background of the plant by reviewing the company website and/or brochure, annual reports, any analyst reports, plant layout (if available), answers to the confidential data collection survey, and performance benchmark data.

The next step is to tour the plant to “see” various aspects of the plant operation, talking to operators and managers, and looking for evidence that the plant adheres to lean manufacturing principles and best practices. Immediately after the tour, observations and impressions are recorded and worksheets are completed.

Following the plant visit, we compile the data, combine the benchmark and assessment ratings within each of the 12 categories, and then aggregate the scores into a composite index that reflects the plant’s “leanness”. Opportunity gaps are identified and company-specific recommendations are formulated to fill them.

This is followed with a PowerPoint presentation that includes the completed scorecard and charts indicating the current “leanness” of the plant. Also included is the competitive benchmarking results showing how your organizations stacks up against other relevant industry players for key performance indicators. The presentation also contains major improvement opportunities and best practices needed to further integrate lean into the organization and move the needle towards performance improvement. The study results and recommendations are presented online to management for review and approval.

By using this approach, you will not only set the stage for enhancing your lean production system, but also pave the way for improving your top and bottom-lines.

What You Get

- An onboarding online meeting to establish the scope of services, determine your goals and objectives, and understand your pain points and expectations.

- One to three-day plant visit (depending on the size and complexity of the operation) to observe operations, interview personnel, collect data, and record observations including evidence of lean principles and practices.

- Completed plant assessment rating sheet and questionnaire.

- Benchmark comparison against other organizations in the industry of key cost, quality, lead time, and productivity performance metrics.

- PowerPoint presentation (via online meeting) summarizing results, opportunities for improvement, and a game plan for subsequent steps.

- Authoritative answer to the frequently asked question: “Where is my organization at on our lean journey?”

How Much Does It Cost?

For your convenience, we offer the Added Value Lean Assessment services as an affordable, low-risk, fixed-priced package. For current pricing and to learn more, please drop me a line at jmiller@PESsolutions.com.

If your company has developed its own performance improvement system, PES can tailor an assessment tool to your criteria and terminology as well.

About PES

Established in 1992, Productivity Engineering Services LLC is an independent Industrial Engineering and Operations Management services firm specializing in the planning, design and implementation of lean manufacturing, warehousing and supply chain operations.

Providing high-quality lean assessments demanded that PES obtain the finest lean education available. The pursuit of excellence led PES to seek their specialized lean education directly from the pioneer in RPA at the prestigious University of Michigan College of Engineering Center for Professional Development (while earning a professional certification in Lean Manufacturing).

PES’ lead assessor relies on over 30 years of real-world experience in the manufacturing sector, advanced education, and well documented tools and techniques to assist in achieving professional, practical, and highly actionable assessments.

The Next Step!

If the time is right to take your business to the next level, please contact PES at (734) 425-3904 today! Don’t worry, you won’t get stuck in an automated phone tree or have to endure a pushy sales rep. This is the direct line to Chief Solutions Officer Jeffrey Miller.

Email: jmiller@PESsolutions.com